Why cleaning clothes sustainably is essential for circular fashion

Fashion

Fast fashion's harmful practices have been gaining more and more public attention over the past few years. It’s not just the fashion savvy that has been hooked on the notion of sustainable fashion and become increasingly curious about how to lessen their wardrobe’s environmental impact. We’ve seen a boom of new sustainable brands, upcycling projects and the rise of the pre-loved market. However, one thing that is not talked about enough, yet is essential for achieving sustainability and circularity in fashion is not only what clothes we purchase, but also how we care for them afterwards. An industry research and activist group Fashion Revolution found out that washing, drying, and ironing clothes produces around a quarter (!) of the garment's carbon footprint during its lifespan. Why does no one talk about it?!

Environmental and health impact of cleaning clothes

The less glamorous, alas main part of our interaction with clothing is aftercare! Yet, as an industry, we are not being given the facts. Traditional cleaning cycle processes produce enormous amounts of CO2 and water. An average load uses as much as 80 litres! Cleaning garments at 60°C, followed by tumble drying, produces the equivalent of 3.3 kg of CO2. Assuming that this is done every other day, it would create a shocking number of 603.9 kg of CO2 each year!

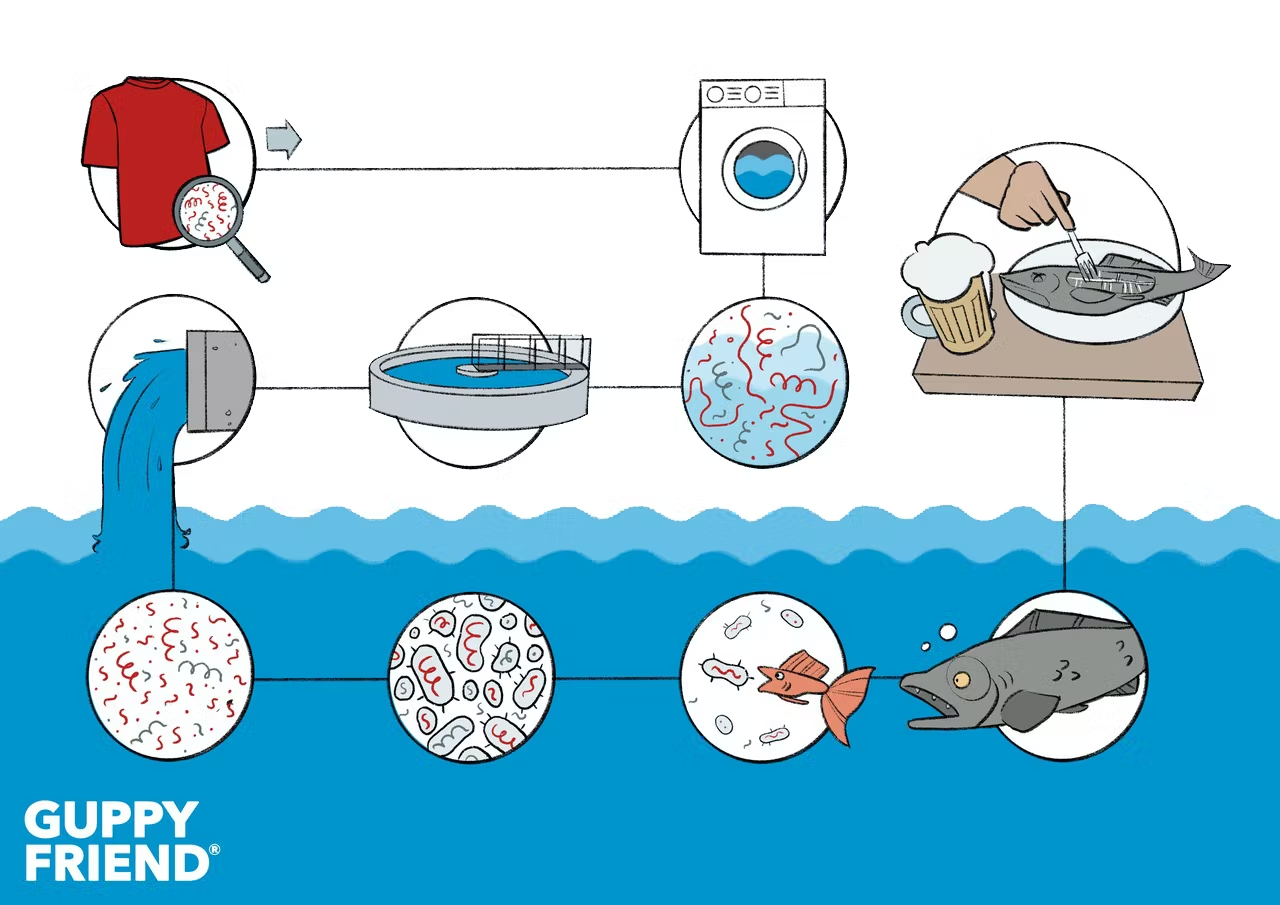

As if this was not scary enough, according to Ellen McArthur Foundation an average wash cycle releases around 700 000 microplastic fibres. Plastic microfibres washed off from synthetic clothes contribute up to 35% of the microplastic found in the oceans. The plastic which is released into our waters is not only detrimental to the environment but later enters the food chain and ends up on our plates. As you can see on the graphic created by the scientists at GUPPY. We are eating and drinking plastic in products such as fish, chicken, honey and beer as well as (tap and bottled) water. Recent research shows that plastic fibres are even present in rainwater too.

As if this was not scary enough, domestic laundry produces surprisingly vast amounts of CO2 and uses immense amounts of water - an average load uses as much as 80 litres! Cleaning garments at 60°C, followed by tumble drying, produces the equivalent of 3.3 kg of CO2. Assuming that each person does that every other day, an individual would create a shocking number of 603.9 kg of CO2 each year, just from washing their clothes!

It is not “just”’ the environment that is being affected, it is every single one of us on an individual level. Apart from microplastic entering our food chain and water supplies, the detergents commonly used for garment cleaning are often toxic and contain chemicals including chlorine bleach, dyes, fragrances and optical brighteners which contaminate our waterways.

Unfortunately, dry cleaning is not the solution to delicate care either. Frankly, it is neither dry nor clean - traditional dry cleaning involves soaking clothes in toxic perchloroethylene ("perc") solvent, which is a human carcinogen. It has been already banned in some countries, including the US in 2007. Workers exposed to this chemical at dry cleaning facilities suffer from headaches, dizziness, and nausea, and evidence suggests that long-term exposure can cause miscarriages and leukaemia. No one should work with perc or wear conventionally dry-cleaned garments on their skin.

Innovations in the textile cleaning industry

Luckily, there are innovations in the industry that are counteracting these issues. At Oxwash, we are on a mission to eliminate the impact of washing on our planet and us, and some other like-minded companies want to do the same.

Microplastic filtration

The filters we use in our washing machines are designed by PlanetCare and capture up to 98% of microplastic fibres released from garments. The filters are regularly returned to PlanetCare and the captured microfibres are stored safely for future use in insulation mats. In 2021 alone, we successfully diverted 22 billion microplastics from the ocean! Such microplastic filters and similar alternatives are also available on the market for individual use.

Water saving

For each cleaning cycle we run, we use 32 litres less water than conventional machines. In our Oxford facility, we reclaim water from the rinse phases to use in the next wash cycle. This saves up to 60% of the water consumption versus a typical commercial washing machine and 70% compared to a domestic washing machine.

Sustainable dry cleaning alternative: wet cleaning

At Oxwash we use wet cleaning technology which is a sustainable dry cleaning alternative suitable for items labelled “dry clean only”. Wet cleaning is a professional cleaning method that uses only water and biodegradable detergents and, in contrast to traditional dry cleaning, avoids the use of chemical solvents such as perchloroethylene or "perc" to achieve clean and soft garments with minimum chemistry addition.

Increasing garment lifespan with sustainable care

The most up-to-date cleaning technology allows for keeping the garments in the loop for longer. How we care for our clothes is critical for increasing the lifespan of the garments. Cleaning garments at low temperatures has been found to prolong the garment's lifespan up to threefold. In most cases, washing at low temperatures is effective in both removing the stains, as well as reducing energy consumption (especially relevant in the current cost of living crisis!). The leading sustainable fashion group, Fashion Revolution, released The Care Label Project, creating a new care symbol – ‘Don’t Overwash’ – to inspire consumers to wash their clothes less, to avoid the harsh and damaging dry cleaning process and to use lower washing temperatures. That’s exactly what we promote and do at Oxwash as well.

Other great innovations in the industry facilitate rejuvenating the condition of the garments, such as the Re_Fresh laundry tablets created by enzyme scientist Harm Kuilderd. The tablets are made from natural enzymes derived from proteins and fungi and have the power to break down the top level of fibres (the most worn down) and gently peel this layer to reveal the vibrant fibres underneath. This refreshes the appearance and colour of clothes, bringing them back to life.

A pair of trousers before and after using the Re_Fresh enzyme tablet

Supporting circular economy

Although fast fashion is still a prevalent large-scale issue, the cricular market is booming: Threadup predicts that resale will outstrip fast fashion by 2030. An observed industry shift presents an opportunity to significantly extend the life of garments and reduce the environmental impact of fashion, as it is estimated that continuing to wear a garment for just nine months longer could decrease its environmental impact by 20– 30%! Circular fashion models, such as rental, resale, and repair all need good quality and sustainable garment cleaning technology to operate. Oxwash powers the circular fashion revolution by providing an expert cleaning platform for our fashion partners, to keep clothes in the life cycle for longer.

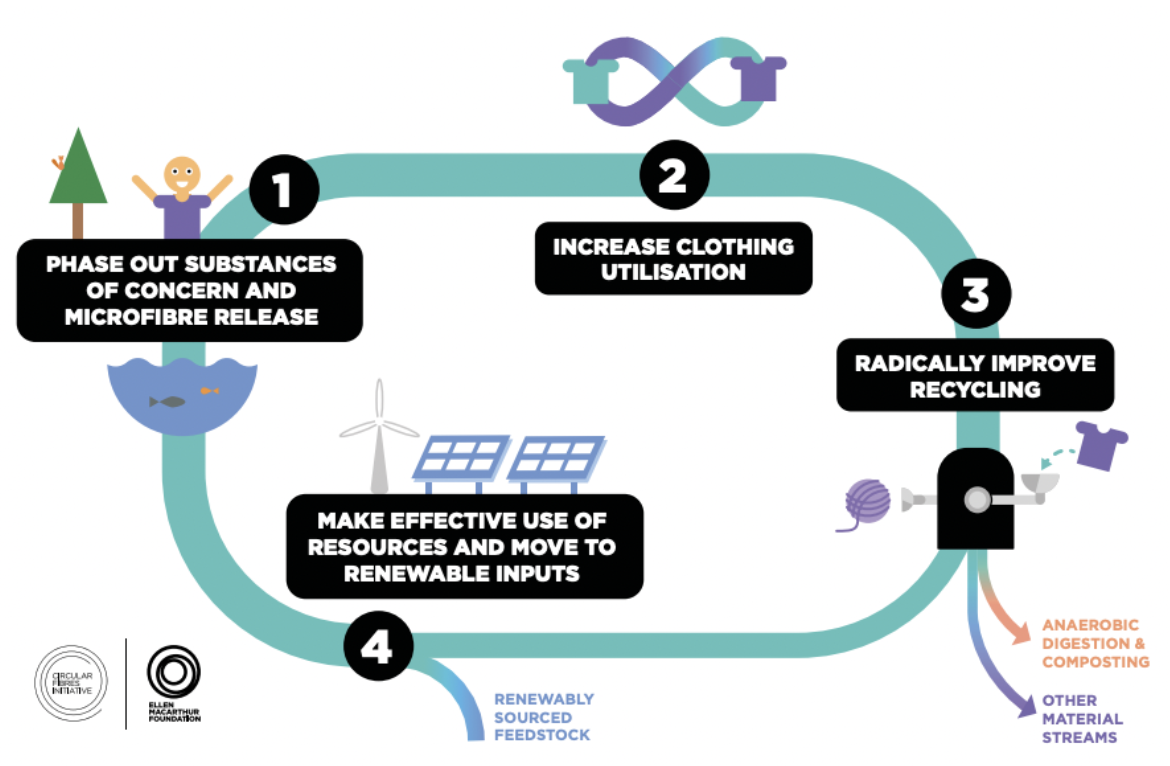

Another leading sustainable fashion group, Ellen MacArthur Foundation, published a New Textiles Economy Report, that included a model outlining the main ambitions for a sustainable fashion economy. As you can see, these 4 main points of concern all circle back to how we clean our clothes. As you can see below, we need to phase out substances of concern (carcinogenic perc, and toxic detergents) as well as plastic microfibre release. Next, we need to increase the utilisation of clothing to keep them in the loop for longer. When we clean clothes in a gentle and sustainable manner, we increase their longevity and allow them to be resold, repurposed or upcycled. What is also immensely important for a transformation towards circular fashion, is improving the efficiency of use of the resources and moving to renewable energy. We care deeply about each of these factors at Oxwash and lead our business on these fundaments by preventing microplastic from entering the oceans, supporting operations of sustainable fashion companies, being carbon neutral, and on our way to becoming net zero with the Science Based Targets initiative.

Takeaway

Cleaning clothes is the backstage of the fashion industry that is not being discussed enough when it comes to its environmental impact. Nevertheless, it is and will increasingly continue to be the backbone of circular fashion. To decrease cleaning's impact on the environment, we need to use technology that utilises low temperatures, saves water, reduces CO2 emissions, and filters out microplastics. The industry has to be gradually leaning towards circular fashion models such as second-hand and rental, and sustainable cleaning is an inseparable part of this journey. Find out more about what we do to reduce cleaning impact on the planet here.

Related Articles

B Corp™ certified.

Surpassing NHS-grade disinfection.